Hydrogen penetration into the steel

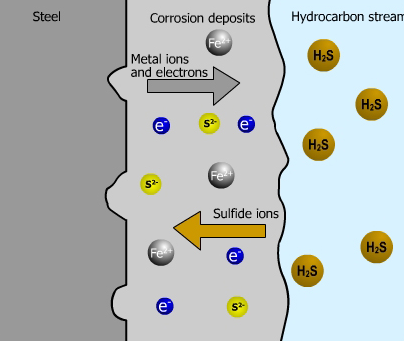

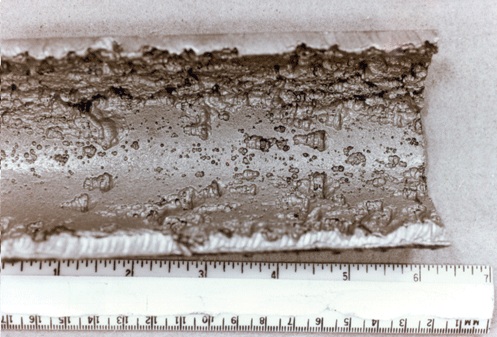

An important negative aspect is the fact that H2S significantly enhances the process of hydrogen absorption (hydrogen penetration into the steel). If the maximum proportion of diffusible hydrogen in steel is 4% of the total amount of reduced hydrogen during corrosion in acidic environments, while the hydrogen sulfide-containing solutions in this figure reaches 40%. The presence of only moisture in a gas entails metal corrosion, the simultaneous presence of the H2S, O2 and H2O is the most unfavorable from the point of view of corrosion. Due to the corrosive action of hydrogen sulfide included in the gas, it is significantly reduced the service life of equipment and facilities in the production, transportation, processing and use of oil and gas (up to 5 years).

To date, significant oil and gas production facilities involved in the production, processing, transportation of hydrogen sulfide containing products. Therefore, to protect the metallic surface of equipment and piping from corrosion damage caused by the presence of hydrogen sulfide in oil or gas well as well as in the condensation water is possible to efficiently and economically using corrosion inhibitors.

Corrosion inhibitors are developed and manufactured by Himipex Oil for use in facilities for the production, preparation and transportation of oil and gas for protection against corrosion of underground equipment of wells with high corrosiveness of the produced products, due to the presence large amounts of H2S in the system.

We propose you examples of the use of corrosion inhibitors of Defender series in various fields with H2S content in the produced fluids from 150 to 1000 ppm. The table shows the results of our products applying at the mentioned above fields with saturating amounts of H2S in the fluid of 150, 500 and 1000 ppm. The corrosion rate was determined by gravimetric method of weight loss coupons of carbon steel.