Persian Gulf countries exploit significant amount of power facilities for the population needs. Thus, Saudi Arabia possesses capacity of power facilities in the amount of 50 GW and, according to the forecasts, there is a need to put into operation additional capacity in the amount of 30 GW till 2020 because of population growth.

Operation of gas turbines while using as combustible heating oil received from crude oil, which is produced in Persian Gulf, results number of operational problems: the reduce of turbines repairing time, the turbines’ capacity loss, equipment’s failure etc. That is caused by high substance of compounds in the oil: vanadium, nickel, sodium. For example, the substance of vanadium in the residual fuel oil can reach 5000 ppm.

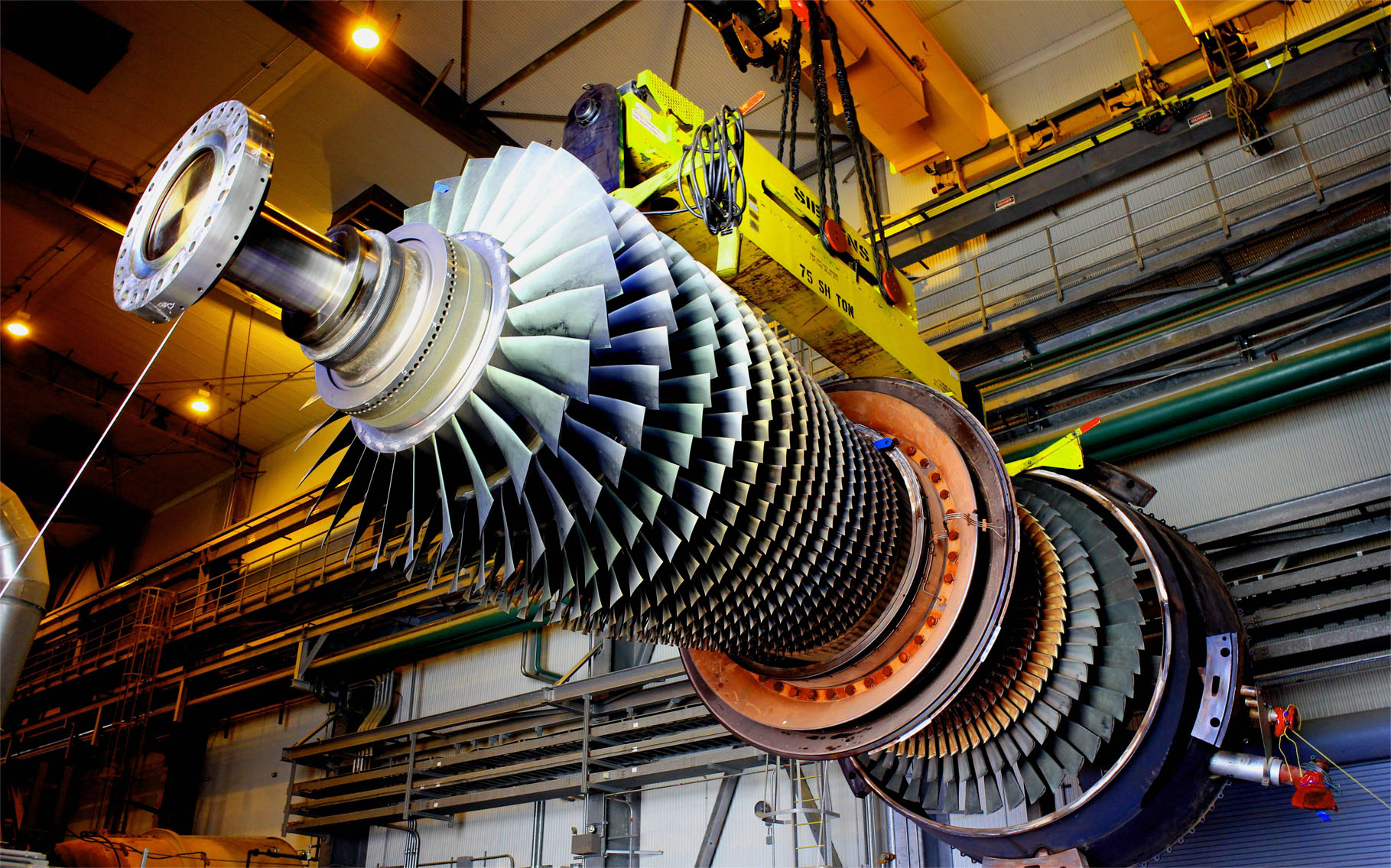

The biggest complications are caused by ash deposits on the blades of the turbines, because they reduce its useful capacity and efficiency and also significantly reduce the terms of turbines work between pauses for deposits removal. Even more complications in the process of gas turbines work are caused by presence of vanadium in the oil, that results significant corrosion of turbine’s equipment. The work duration of some turbines on the residual oil fuel, with the high content of sodium, sulfates, vanadium is only 200-300 h. The formation of the deposits on the blades of turbines of low melting salts – ash deposits - is the the reason of metal corrosion in the condition of high temperatures. The formation of the cinder deposit and deposits on hot surfaces of diesel or gas turbine happens because of sticking of baked ash, which are produced in the process of low-volatility fuel combustion.

Nowadays there are 3 directions in order to predict the deposits of corrosive aggressive ash on the blades of the turbine and on the surfaces of air generators:

1) Arranging of the processes of fuel oil combustion with not full burning-out of the carbon;

2) Rejection of components which are harmful for metal’s burning out from the fuel;

3) Addition of special additive (corrosion and deposit inhibitors) to the fuel oils.

The solution of the problem of vanadium corrosion with the help of HIMIPEX company’s inhibitors.