Particular properties of corrosion control in Persian Gulf countries

Persian Gulf countries control more than 40% of the world's oil reserves. Huge investments in the oil and gas industry in these countries also include the cost of product loss, repair and replacement of expensive equipment and pipelines. A significant part of these costs is spending on solving the problems caused by strong corrosion of metal equipment and pipelines in the oil and gas production and transportation processes. For example, these costs to Saudi Arabia in 2011 amounted to 24.84 billion USD, and for the UAE - 14.26 billion USD. It should be noted also that the cost of repairs for the offshore production will be calculated by millions USD. For replacement the key long pipelines of the large diameter we are talking about tens of millions USD. For older oil fields with hundreds of pipelines 4-5 leaks per year, caused by the corrosion of pipes, is quite normal.

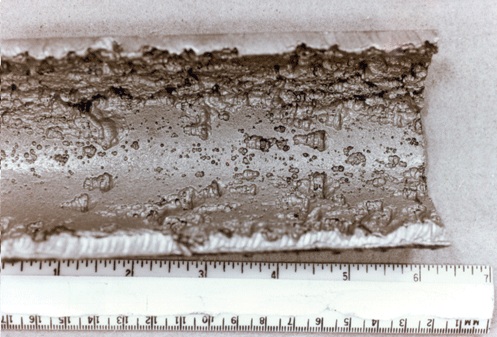

Oil and gas industry, as a rule, works in very hard conditions, such as deserts and deep sea. In such conditions, corrosion is very serious and difficult for solving problem. In desert conditions the following factors can contribute to corrosion: variation of wet and dry weather, high temperatures (about 50°C) and high humidity for the most part of the year, the salinity of the groundwater. Also, typical for this region existence of the large number of corrosive gases СО2 and H2S in the stream of produced oil, gas condensate and gas stimulate the destructive corrosion processes.

Losses from corrosion can be significantly reduced by using a number of known and effective methods. One of them, and the most simple, cheap and efficient is using corrosion inhibitors

H2S and

CO2.